Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

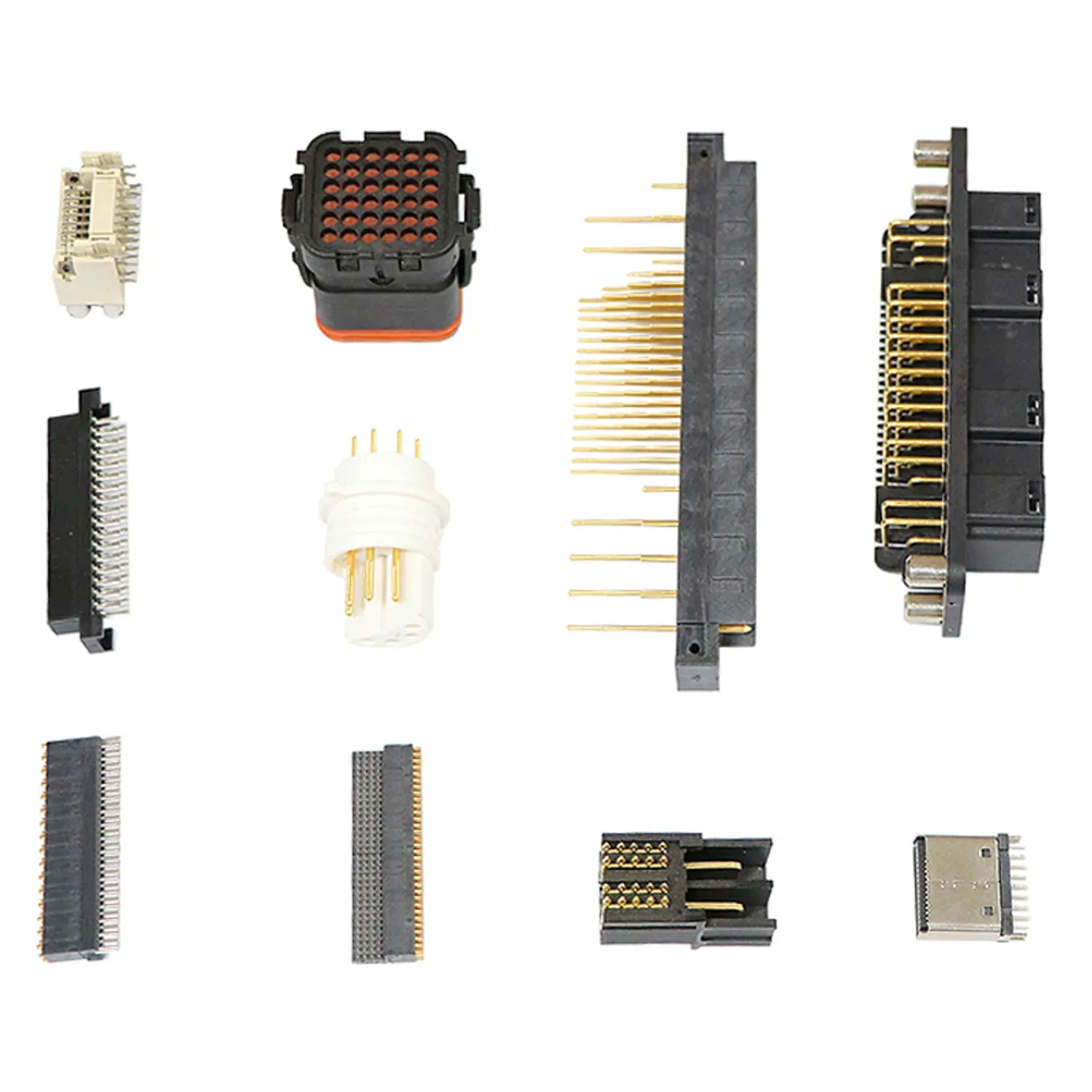

What Material is Used for Electrical Connectors?

Electrical connectors are vital components in countless applications, from consumer electronics to industrial machinery. Their primary function is to enable electrical signals or power to pass from one device to another, ensuring reliable and efficient performance. But what material is used for electrical connectors, and why are these materials chosen? This comprehensive guide will delve into the materials commonly used in electrical connectors, explaining their properties, benefits, and typical applications. For high-quality plastic connector molds, explore SZOMK's extensive collection. We are your trusted injection molding company, providing top-notch plastic connector molding solutions.

Common Materials for Electrical Connectors

Understanding the materials used in electrical connectors can significantly impact the performance and reliability of your electrical systems. Here's a closer look at the most commonly used materials:

Copper and Copper Alloys

Copper is the most widely used material for electrical connectors due to its excellent conductivity and relatively low cost. Copper alloys, such as brass and bronze, are also popular choices. These materials offer a balance between conductivity, durability, and cost-effectiveness.

Properties and Benefits of Copper

Copper's high electrical conductivity makes it ideal for connectors, allowing efficient electricity flow. Its corrosion resistance, while copper can tarnish, ensures it resists corrosion well, especially when coated. Additionally, copper and its alloys possess mechanical strength, ensuring long-lasting connections.

Aluminum

Aluminum is another material used in electrical connectors, particularly in power transmission applications. Although it has lower conductivity than copper, aluminum is much lighter, which can be beneficial in specific contexts.

Properties and Benefits of Aluminum

Aluminum's lightweight nature makes it easier to handle and install, especially in overhead power lines. It's generally more cost-effective than copper, providing an adequate conductivity level for many applications.

Nickel and Nickel Alloys

Nickel is often used in electrical connectors for its corrosion resistance and ability to withstand high temperatures. Nickel alloys, such as nickel-copper (Monel) and nickel-chromium, are also used in environments where extreme conditions are a concern.

Properties and Benefits of Nickel

Nickel can withstand harsh environments, making it suitable for industrial applications. Its high-temperature stability ensures it maintains properties at high temperatures, and its durability provides reliable long-term performance.

Gold

Gold is used in high-performance and high-reliability applications, such as aerospace and telecommunications. Gold-plated connectors provide excellent corrosion resistance and conductivity.

Properties and Benefits of Gold

Gold's exceptional conductivity ensures minimal signal loss. It does not tarnish or corrode, maintaining a reliable connection. Gold's high reliability makes it suitable for critical applications where failure is not an option.

Silver

Silver is another material used for its superior conductivity. However, due to its higher cost, silver is typically used in specialized applications where maximum conductivity is essential.

Properties and Benefits of Silver

Silver surpasses all other metals in electrical conductivity. It ensures minimal signal loss with low contact resistance, but due to its high cost, it's often used sparingly in critical applications.

Material Selection for Specific Applications

Choosing the right material for electrical connectors depends on the specific requirements of the application. Factors such as electrical conductivity, mechanical strength, corrosion resistance, and cost must all be considered.

Consumer Electronics

In consumer electronics, such as smartphones and laptops, gold-plated connectors are often used due to their excellent conductivity and reliability. Copper and brass are also common, providing a good balance between performance and cost.

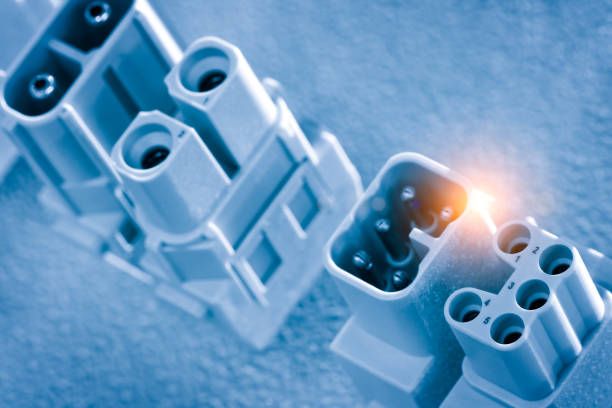

Industrial Machinery

Industrial applications often require materials that can withstand harsh conditions. Nickel and nickel alloys are preferred for their durability and resistance to corrosion and high temperatures. Copper alloys are also frequently used due to their mechanical strength and conductivity.

Automotive Industry

The automotive industry requires connectors that can handle various environmental conditions, from extreme temperatures to vibrations. Copper and aluminum are commonly used due to their conductivity and cost-effectiveness. Nickel-plated connectors are also employed for their durability.

Aerospace and Telecommunications

In aerospace and telecommunications, where reliability and performance are critical, gold and silver are the materials of choice. These connectors ensure minimal signal loss and can operate in extreme conditions.

Emerging Trends in Electrical Connector Materials

As technology advances, new materials and coatings are being developed to improve the performance and reliability of electrical connectors.

Conductive Polymers

Conductive polymers are an emerging material in the electrical connector industry. These materials offer flexibility, lightweight properties, and good conductivity, making them suitable for various applications, including wearable electronics and flexible circuits.

Graphene

Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, is gaining attention for its exceptional electrical and thermal conductivity. Although still in the research phase, graphene has the potential to revolutionize electrical connectors with its unique properties.

Composite Materials

Composite materials, combining metals with polymers or ceramics, are being explored to enhance connector performance. These materials aim to provide the best of both worlds: the conductivity of metals and the lightweight, durable properties of polymers.

The Importance of Material Choice in Electrical Connectors

Selecting the appropriate material for electrical connectors is crucial for ensuring the performance and longevity of electrical systems. Each material offers distinct advantages, and the right choice depends on the specific requirements of the application.

Factors to Consider

When choosing materials for electrical connectors, consider the following factors: electrical conductivity to ensure the material can conduct the required electrical signals efficiently, mechanical strength to withstand physical stress and environmental conditions, corrosion resistance to select materials that can resist corrosion, especially in harsh environments, and cost to balance performance with cost to ensure the solution is economical.

Real-World Examples

For instance, in high-vibration environments like automotive or aerospace applications, nickel-plated connectors might be preferred for their durability and resistance to wear. In contrast, in consumer electronics where miniaturization and reliability are critical, gold-plated connectors are often the go-to choice.

Conclusion

Understanding what material is used for electrical connectors is essential for optimizing the performance and reliability of electrical systems. From the superior conductivity of silver and gold to the cost-effective and reliable properties of copper and aluminum, each material serves a unique purpose in various applications. Emerging materials like conductive polymers and graphene promise to further enhance the capabilities of electrical connectors, paving the way for new innovations.

When selecting materials for electrical connectors, consider the specific requirements of your application to ensure you choose the right material that offers the best balance of performance, durability, and cost. This careful selection process will help maintain the integrity and efficiency of your electrical systems, whether in consumer electronics, industrial machinery, automotive applications, or high-stakes fields like aerospace and telecommunications.

For those seeking high-quality plastic components for electrical connectors, SZOMK offers unparalleled expertise and reliability. As a leading plastic injection molding company, SZOMK specializes in producing durable, precise, and cost-effective plastic parts tailored to meet your specific needs. Our commitment to quality and customer satisfaction ensures that you receive the best solutions for your electrical connector applications. Trust SZOMK for your plastic injection molding needs and experience the difference in performance and reliability. Explore our professional plastic injection molding services today.