Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

Connector Mold

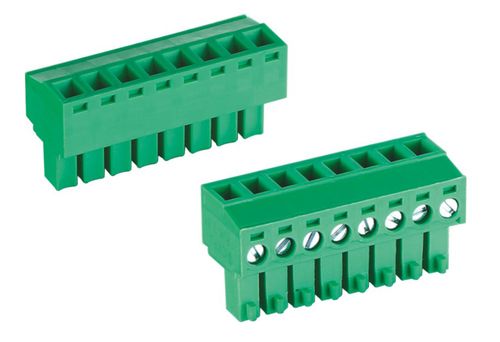

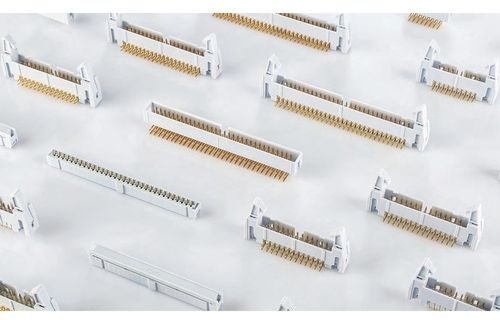

Electrical connector molds are critical in creating components that bridge electrical signals and power in circuits. These molds are precision-engineered to produce connectors with exact dimensions and tolerances, ensuring seamless integration into various electronic systems. Whether you need a simple design for consumer electronics or a complex configuration for industrial machinery, our electrical connector molds deliver outstanding results.

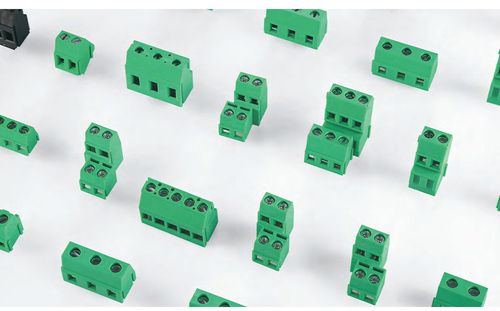

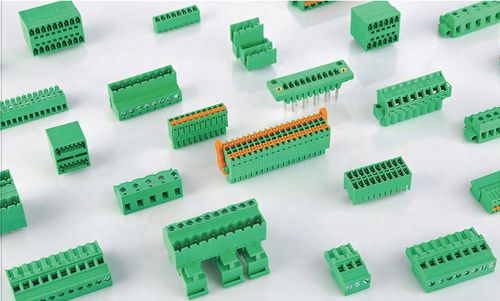

Different Types of Electrical Connector Molds

Consumer Electronics Connector Molds

Consumer electronics connector molds are designed to produce connectors used in everyday electronic devices like smartphones, tablets, and laptops. These molds ensure the connectors have precise dimensions and high reliability, which is essential for seamless connectivity and performance in consumer electronics. These molds cater to the need for fast data transfer and power delivery in modern gadgets.

Automotive Electrical Connector Molds

Automotive electrical connector molds are engineered to withstand the harsh conditions of automotive environments. These connectors are crucial for ensuring reliable electrical connections in vehicles, including systems like lighting, infotainment, and engine management. Automotive electrical connector molds are designed for durability and precision, ensuring connectors can endure vibrations, temperature fluctuations, and exposure to chemicals.

Medical Electrical Connector Molds

Medical electrical connector molds are designed to produce connectors used in medical devices and equipment. These connectors must meet high standards of safety, reliability, and hygiene. Medical electrical connector molds ensure that the connectors produced are biocompatible and can withstand sterilization processes. These molds are critical for applications in diagnostic equipment, patient monitoring systems, and therapeutic devices.

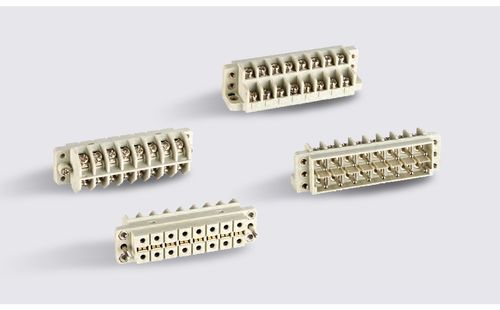

Aerospace Electrical Connector Molds

Aerospace electrical connector molds are used to manufacture connectors that meet the rigorous demands of the aerospace industry. These connectors must be lightweight, durable, and able to withstand extreme temperatures and environmental conditions. Aerospace electrical connector molds are designed with precision to ensure the highest quality connectors for applications in aircraft, spacecraft, and satellite systems.

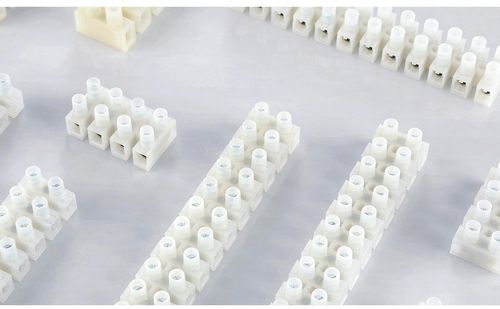

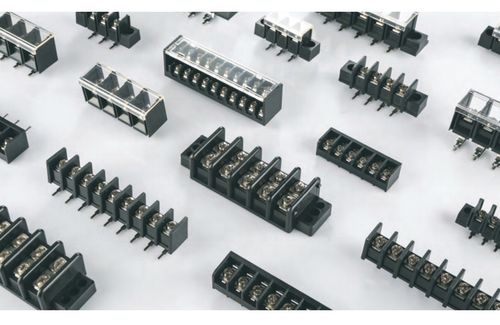

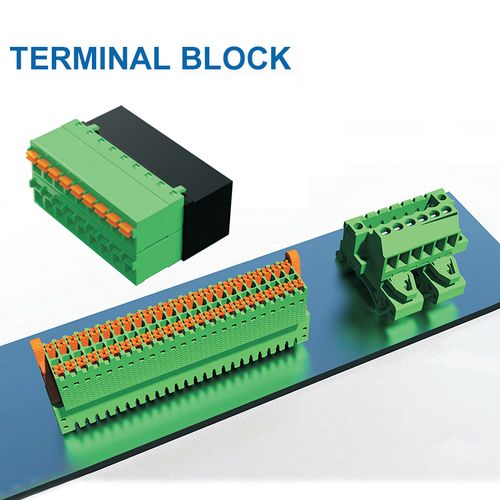

Industrial Electrical Connector Molds

Industrial electrical connector molds produce connectors used in various industrial applications, including machinery, automation systems, and heavy equipment. These molds are designed to create connectors that can handle high currents, resist corrosion, and endure mechanical stresses. Industrial electrical connector molds ensure connectors meet the robust requirements of industrial environments.

Custom Electrical Connector Molds

Custom electrical connector molds are tailored to meet specific design requirements and applications. These molds offer flexibility in terms of material selection, connector shape, and size. Custom electrical connector molds are ideal for creating unique connectors that cater to specialized needs in various industries. By providing custom solutions, SZOMK ensures that every connector meets the exact specifications and performance standards required by our clients.

FAQs for Connector Injection Molding

FAQs for Connector Injection Molding

1. What is connector injection molding?

2. What materials are used for molded connectors?

3. What industries use connector molds?

4. What are the benefits of using injection molding for connectors?

5. Can SZOMK create custom connector molds?

6. What is the typical lead time for connector injection molding projects?

7. How do I select the right material for my connector injection molding project?