Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

What Is the Dfference between Injection Molding and Precision Molding?

In the realm of manufacturing, terms like injection molding and precision molding often intertwine, creating a tapestry of confusion. Today, we embark on a journey to demystify these processes, exploring the subtle yet significant differences that set them apart.

Understanding Injection Molding

The Fundamentals

Injection molding is a widely used manufacturing process where molten material is injected into a mold cavity, forming the desired shape as it cools and solidifies. This versatile technique is employed across various industries to produce a myriad of products, from consumer goods to automotive components.

High Volume, Low Cost

One of the key characteristics of injection molding is its ability to produce high volumes of identical parts with remarkable efficiency. The process is known for its cost-effectiveness, making it an ideal choice for large-scale production runs where consistency and speed are paramount.

Versatility in Material Selection

Injection molding accommodates an extensive range of materials, including plastics, metals, and elastomers. This versatility in material selection contributes to its widespread adoption in diverse manufacturing applications.

Precision Molding

The Essence of Precision

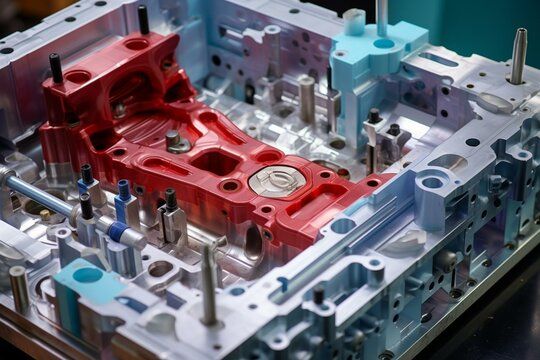

Precision molding, as the name suggests, places a heightened emphasis on achieving exceptionally tight tolerances and exacting specifications. This process is geared towards the production of intricate, high-precision components where accuracy is critical.

Tighter Tolerances, Finer Details

Unlike conventional injection molding, precision molding involves tighter control over parameters such as temperature, pressure, and tooling. This meticulous attention to detail results in parts with finer details, reduced variations, and enhanced dimensional accuracy.

Ideal for Complex Geometries

Precision molding excels in the production of components with complex geometries, intricate features, and micro-sized details. Industries like medical devices, aerospace, and electronics often leverage precision molding to meet the stringent requirements of their applications.

Injection Molding vs. Precision Molding

Tolerance Levels

The primary distinction lies in the tolerance levels achieved by each process. While injection molding provides acceptable tolerances for many applications, precision molding takes it a step further, achieving ultra-precise dimensions that meet the demands of intricate designs.

Volume and Speed

Injection molding thrives in high-volume production scenarios where speed is crucial. Precision molding, while offering unparalleled accuracy, may involve slightly slower production rates due to the meticulous control over parameters.

Application Focus

Injection molding is a versatile workhorse suitable for a broad range of applications. Precision molding, on the other hand, shines in applications demanding the utmost accuracy, especially in industries where the components' performance hinges on minute details.

SZOMK Electronics: Precision in Every Mold

At SZOMK Electronics, precision is not just a feature; it's our commitment. We understand the nuanced differences between injection molding and precision molding, and our expertise lies in delivering molds that exceed expectations. From intricate electronic components to precise enclosures, every mold we craft is a testament to our dedication to precision manufacturing.

Whether your project demands the efficiency of injection molding or the exacting standards of precision molding, trust SZOMK Electronics to deliver molds that meet your unique requirements.

Choosing the Right Process for Your Project

The choice between injection molding and precision molding ultimately depends on the specific needs of your project. If you require high-volume production with acceptable tolerances, injection molding may be the ideal choice. For applications demanding utmost precision and intricate details, precision molding is the pathway to perfection.

Precision Unveiled

In conclusion, the differences between injection molding and precision molding are nuanced yet impactful. Each process has its strengths and is tailored to meet specific manufacturing requirements. At SZOMK Electronics, we navigate these subtleties with finesse, delivering molds that embody precision in every detail.

Conclusion

Understanding the distinctions between injection molding and precision molding is crucial when selecting the right process for your manufacturing needs. While injection molding is ideal for high-volume, cost-effective production with versatile material options, precision molding offers unparalleled accuracy, making it the go-to choice for intricate designs and applications requiring tight tolerances.

At SZOMK Electronics, we excel in both injection molding and precision molding, ensuring that every project is handled with the highest level of expertise and attention to detail. Our advanced facilities and skilled team allow us to deliver molds that meet the most exacting standards, regardless of the complexity or scale of your project.

Whether your manufacturing needs require the efficiency of injection molding or the precision of high-tolerance molding, SZOMK Electronics is your trusted partner. We are committed to providing solutions that not only meet but exceed your expectations, ensuring that every product is crafted with precision and excellence.

Choose SZOMK Electronics for your next project, and experience the difference that expert precision and dedication can make.