Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

Injection Moulding vs 3D Printing: Which One Should I Choose?

In the fast-evolving landscape of manufacturing, the choice between injection molding and 3D printing can significantly impact your production process. Both techniques offer unique advantages, but the decision ultimately depends on your specific requirements and project parameters.

What is Injection Molding?

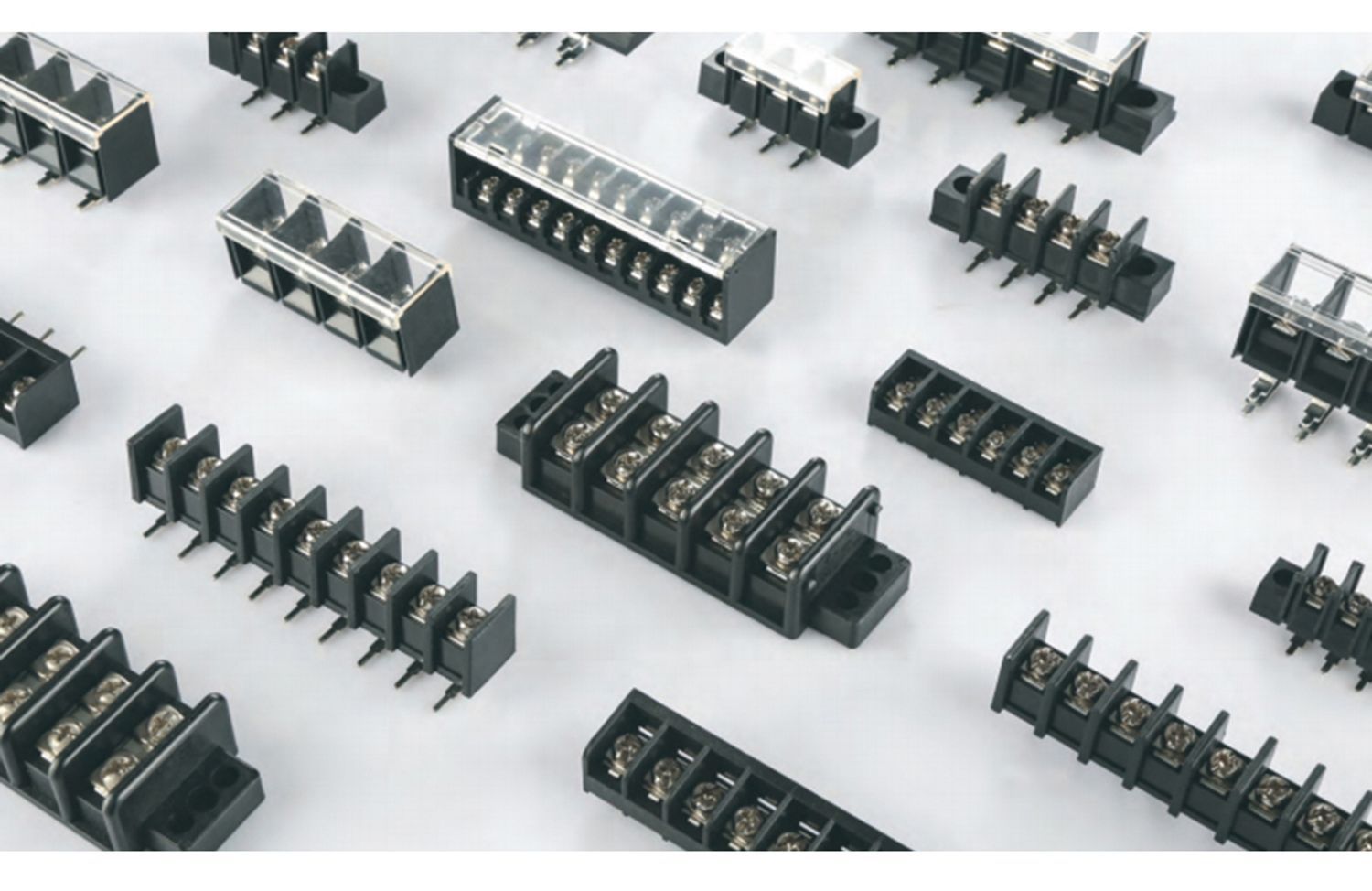

Injection molding has long been the go-to method for mass production. It involves injecting molten material, typically plastic, into a mold cavity where it solidifies. This process is highly efficient and delivers high-quality, consistent results. While the initial setup costs for injection molding may be higher, the per-unit cost decreases substantially with larger production runs.

One of the standout features of injection molding is its ability to produce intricate and detailed parts with tight tolerances. This makes it ideal for industries requiring precision, such as automotive and medical devices. Additionally, a wide range of materials, including thermoplastics and thermosetting polymers, can be used in injection molding, providing versatility in material selection.

What is 3D Printing?

On the other hand, 3D printing, also known as additive manufacturing, has emerged as a transformative technology. It builds objects layer by layer from digital models, offering unparalleled design freedom. This flexibility is especially advantageous for rapid prototyping and small-batch production. Unlike injection molding, 3D printing doesn't require expensive molds, making it cost-effective for low-volume projects.

The appeal of 3D printing lies in its ability to create complex geometries and prototypes quickly. This makes it an excellent choice for industries like aerospace and consumer electronics, where innovation and rapid development are critical. However, it's worth noting that the per-unit cost in 3D printing may be higher than in injection molding for larger production runs.

Choosing the Right Technology for Your Needs

Cost Considerations

If you're looking to produce a large quantity of identical parts, injection molding may be the more cost-effective option in the long run. However, for small-batch or customized production, 3D printing might be the more economical choice due to its lower initial costs.

Speed and Flexibility

3D printing shines in terms of speed and flexibility. It allows for quick design iterations and the production of complex parts without the need for tooling changes. If time-to-market is a crucial factor for your project, 3D printing could be the ideal solution.

Material Selection

Injection molding offers a broader range of materials, including those with specific properties such as high strength or heat resistance. If your project demands a specialized material, injection molding might be the better fit, especially for parts that require durability or high performance.

Prototyping vs. Production

If your primary goal is rapid prototyping, 3D printing provides unmatched agility. It enables the creation of functional prototypes with complex geometries in a short time. However, if you're moving into large-scale production, injection molding's efficiency and lower per-unit cost become more advantageous.

Conclusion

In the injection molding vs. 3D printing debate, there is no one-size-fits-all answer. Each technology brings unique strengths to the table, and your decision should align with your project goals, budget constraints, and production requirements. Whether you prioritize precision and cost-effectiveness or value rapid prototyping and design flexibility, understanding the nuances of each method is crucial in making an informed choice.

At SZOMK Electronics, we specialize in both injection molding and 3D printing, offering tailored solutions that meet the specific needs of your project. Our expertise ensures that, whether you choose the precision and efficiency of injection molding or the flexibility and innovation of 3D printing, you'll receive top-quality results. Partner with SZOMK Electronics for a manufacturing process that aligns perfectly with your goals, and take the next step in your production journey with confidence.