Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

What Is the ABS Plastic Injection Molding Process?

Mastering the ABS plastic injection molding process is essential for achieving high-quality, consistent results in manufacturing. Proper understanding allows for efficient production, cost-effectiveness, and the ability to create complex parts with precision. By delving into the intricacies of this process, manufacturers can optimize their operations and enhance their competitiveness in the market.

Understanding ABS Plastic

Definition and Composition of ABS Plastic

ABS plastic, short for acrylonitrile butadiene styrene, is a thermoplastic polymer known for its exceptional strength and versatility. Composed of three monomers - acrylonitrile, butadiene, and styrene - ABS combines the desirable properties of each component to create a material that is both rigid and impact-resistant. This unique composition makes ABS plastic ideal for a wide range of applications, from automotive components to consumer electronics.

Properties of ABS Plastic

ABS plastic boasts a host of desirable properties that make it well-suited for injection molding applications. Its durability, impact resistance, and chemical resistance ensure longevity and reliability in various environments. Additionally, ABS plastic can be easily molded into intricate shapes without sacrificing structural integrity, making it a preferred choice for complex parts. Its ability to maintain dimensional stability and withstand temperature fluctuations further enhances its appeal across industries.

Applications of ABS Plastic in Various Industries

The versatility of ABS plastic lends itself to a multitude of applications across different sectors. In the automotive industry, ABS is used for manufacturing interior and exterior components, such as dashboard panels, trim pieces, and bumpers, due to its durability and impact resistance. In the electronics sector, ABS is prized for its electrical insulation properties, making it ideal for housing components in devices like computers and appliances. Furthermore, ABS plastic finds applications in consumer goods, including toys, household appliances, and sporting equipment, where its strength and aesthetic appeal are valued. As we delve deeper into the ABS plastic injection molding process, we'll uncover the myriad ways in which this versatile material can be utilized to create innovative products for various industries.

The Injection Molding Process

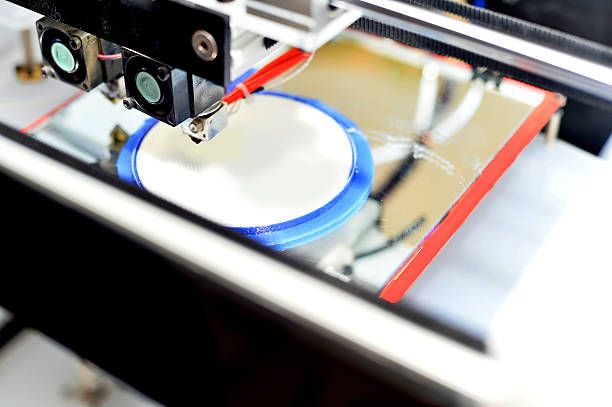

Injection molding is a manufacturing process used to produce parts and components by injecting molten material into a mold cavity. This process is highly versatile and efficient, allowing for the production of complex shapes with high precision and repeatability. In the case of ABS plastic injection molding, the process involves injecting molten ABS material into a mold cavity to create the desired part or product.

Overview of ABS Plastic Injection Molding Steps

In ABS plastic injection molding, several key steps are involved to achieve the desired outcome:

- Mold Design and Preparation: The first step involves designing and preparing the mold that will be used to shape the ABS plastic. This includes designing the part geometry, creating the mold cavity, and ensuring proper cooling channels for efficient molding.

- Melting and Injecting ABS Plastic: Once the mold is prepared, ABS plastic resin is melted and injected into the mold cavity under high pressure. This allows the molten material to flow into all the intricate details of the mold, ensuring precise replication of the part geometry.

- Cooling and Solidification: After the molten ABS plastic is injected into the mold cavity, it is cooled rapidly to solidify and take the shape of the mold. Proper cooling is crucial to ensure uniform solidification and prevent defects in the final part.

- Ejection of the Molded Part: Once the ABS plastic has solidified, the mold opens, and the newly formed part is ejected from the mold cavity. This process may be automated or manual, depending on the complexity of the part and the molding equipment used.

Importance of Precise Temperature and Pressure Control

Achieving precise temperature and pressure control is paramount in ABS plastic injection molding to ensure the quality and consistency of the final parts. Proper temperature control helps to prevent issues such as warping, shrinkage, and degradation of the ABS material. Maintaining the correct injection pressure ensures that the molten ABS plastic fills the mold cavity completely and evenly, minimizing defects such as voids or sink marks. By carefully monitoring and adjusting these parameters throughout the injection molding process, manufacturers can optimize production efficiency and produce high-quality ABS plastic parts consistently.

Advantages of ABS Plastic Injection Molding

Cost-effectiveness and Efficiency

ABS plastic injection molding offers significant cost savings and efficiency gains compared to other manufacturing processes. The ability to produce large volumes of parts quickly and accurately reduces production time and labor costs, making it a cost-effective solution for mass production.

Key Advantages of ABS Plastic

ABS plastic offers several key advantages that make it an ideal choice for injection molding applications:

- Impact Resistance: ABS plastic is highly resistant to impact, making it suitable for parts that may be subjected to mechanical stress or rough handling.

- Chemical Resistance: ABS plastic is resistant to a wide range of chemicals, making it suitable for use in environments where exposure to corrosive substances is a concern.

- Recyclability: ABS plastic is recyclable, allowing for sustainable manufacturing practices and reducing environmental impact.

Comparison with Other Materials

When compared to other materials commonly used in injection molding, such as thermoplastics and thermosets, ABS plastic offers unique advantages. Its combination of strength, impact resistance, and ease of processing make it a preferred choice for a wide range of applications. Additionally, ABS plastic can be easily molded into complex shapes without sacrificing structural integrity, giving manufacturers greater design flexibility and versatility.

Considerations and Best Practices

When designing parts for ABS plastic injection molding, several factors must be considered to ensure optimal results.

- Part Design: Designing parts with uniform wall thicknesses and adequate ribs or radii helps to prevent stress and improve strength. Additionally, maintaining the correct ratio of radius to wall thickness minimizes shrinkage during the molding process.

- Wall Thickness: Uniform wall thickness is essential for preventing defects such as warping and sink marks. Designing parts with consistent wall thicknesses ensures even cooling and solidification, resulting in high-quality finished products.

- Rib Design: Incorporating ribs into part designs can enhance strength and rigidity without significantly increasing weight. Properly designed ribs distribute stress evenly throughout the part, reducing the risk of failure under load.

Importance of Drying ABS Material Before Processing

Before processing ABS plastic, it is crucial to ensure that the material is thoroughly dried to prevent moisture absorption.

- Moisture Absorption: ABS plastic has a tendency to absorb moisture from the surrounding environment, which can lead to defects such as bubbles or surface imperfections in the final product.

- Drying Temperature: Drying ABS material at the correct temperature and for the appropriate duration is essential to remove moisture effectively. Typically, temperatures ranging from 80-95°C are recommended, with drying times of three to four hours to achieve optimal results.

Temperature, Pressure, and Speed Control

Maintaining precise control over temperature, pressure, and speed is critical in ABS plastic injection molding to achieve consistent results.

- Molding Temperature Control: Proper temperature control is essential to prevent thermal degradation of the ABS material. Maintaining temperatures within the recommended range (180-230°C) ensures optimal flow and solidification characteristics.

- Injection Pressure: Adjusting injection pressure according to the viscosity of the molten ABS material ensures complete filling of the mold cavity without defects such as voids or sink marks.

- Injection Molding Speed: Balancing injection molding speed is crucial to avoid issues such as burning or thermal decomposition of the plastic material. Optimizing speed ensures proper filling of the mold cavity without compromising part quality.

Applications of ABS Plastic Injection Molding

Diverse Applications of ABS Plastic Molded Parts

ABS plastic injection molding finds applications across various industries due to its versatility and durability.

- Automotive: ABS plastic is used in automotive applications such as interior and exterior components, including dashboards, trim panels, and bumper covers.

- Electronics: ABS plastic is prized for its electrical insulation properties, making it suitable for housing components in electronic devices such as computers, appliances, and consumer electronics.

- Consumer Products: ABS plastic is widely used in consumer products such as toys, household appliances, and sporting equipment due to its strength, impact resistance, and aesthetic appeal.

Sustainability and Recyclability Aspects

ABS plastic injection molding offers sustainability benefits, including recyclability and eco-friendly manufacturing practices.

- Recyclable: ABS plastic is recyclable, allowing for the reuse of scrap material and reducing waste in the manufacturing process.

- Sustainable Practices: By employing sustainable practices such as energy-efficient molding processes and using recycled materials, manufacturers can minimize their environmental footprint and contribute to a greener future.

Conclusion

Ready to start your ABS plastic injection molding project? Contact SZOMK today to discuss your needs and requirements. Our team of experts is standing by to assist you every step of the way. For more information and resources on ABS plastic injection molding and our services, visit the SZOMK website. Explore our portfolio, learn about our capabilities, and discover how we can help bring your ideas to life.

You may also interested: