Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

What are the Raw Materials for Injection Molding?

Injection molding is a versatile and widely used manufacturing process in various industries, including automotive, medical, consumer electronics, and packaging. It involves injecting molten material into a mold to create a specific shape. The success of this process largely depends on the choice of raw materials. In this comprehensive guide, we will explore the different raw materials for injection molding, their properties, and how they influence the final product's quality and performance.

Understanding Injection Molding

Before diving into the specifics of raw materials for injection molding, it's essential to understand the injection molding process itself. Injection molding is a manufacturing technique for producing parts by injecting molten material into a mold. It can be performed with various materials, including metals, glass, elastomers, and most commonly, thermoplastic and thermosetting polymers.

The Injection Molding Process

- Clamping: The mold is closed by a clamping unit, which holds the mold halves together.

- Injection: Molten plastic is injected into the mold cavity at high pressure.

- Cooling: The injected plastic cools and solidifies in the mold.

- Ejection: The final product is ejected from the mold once it has cooled and solidified.

Now, let's delve into the specific raw materials used in injection molding.

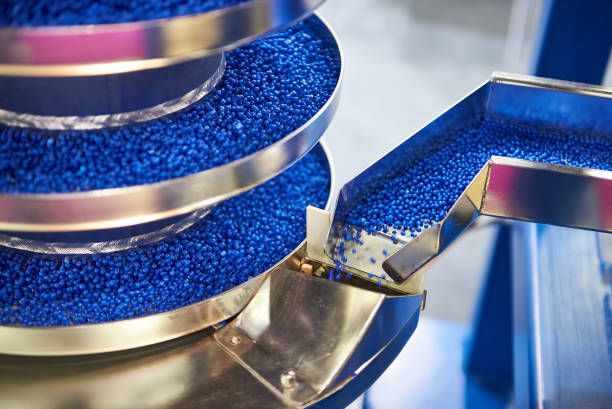

Thermoplastics: The Primary Raw Material for Injection Molding

Thermoplastics are the most commonly used raw materials for injection molding. They become pliable or moldable above a specific temperature and solidify upon cooling. Here are some of the most popular thermoplastics used in injection molding:

Polypropylene (PP)

Polypropylene is a versatile and cost-effective thermoplastic known for its excellent chemical resistance, low density, and high impact strength. It is widely used in automotive parts, packaging, and consumer goods.

Read more: What Is Polypropylene Injection Molding?

Acrylonitrile Butadiene Styrene (ABS)

ABS is a robust and impact-resistant thermoplastic. It is easy to mold, making it ideal for applications in automotive parts, consumer electronics, and toys. Its glossy finish and ability to be colored make it a favorite for aesthetic applications.

Read more: What Is the ABS Plastic Injection Molding Process?

Polyethylene (PE)

Polyethylene is another widely used thermoplastic with excellent chemical resistance and low moisture absorption. It is available in various densities, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE). PE is commonly used in packaging, containers, and piping.

Polycarbonate (PC)

Polycarbonate is known for its high impact resistance and optical clarity. It is used in applications requiring transparency and strength, such as eyewear lenses, medical devices, and automotive lighting components.

Nylon (Polyamide)

Nylon is a strong and durable thermoplastic with excellent wear resistance and low friction properties. It is often used in mechanical parts, gears, and bearings.

Thermosetting Plastics: A Durable Choice for Injection Molding

Unlike thermoplastics, thermosetting plastics undergo a chemical change when heated, making them rigid and unable to be remolded. Here are some common thermosetting plastics used in injection molding:

Epoxy Resins

Epoxy resins are known for their strong adhesive properties and chemical resistance. They are commonly used in coatings, adhesives, and composite materials.

Phenolic Resins

Phenolic resins are heat-resistant and provide excellent electrical insulation. They are used in electrical components, household appliances, and automotive parts.

Polyurethane (PU)

Polyurethane is a versatile thermosetting plastic used in a wide range of applications, including foam seating, insulation panels, and elastomeric wheels and tires.

Elastomers: Flexibility in Injection Molding

Elastomers are a type of polymer with viscoelasticity (elasticity and viscosity), often having a low Young's modulus and high failure strain compared to other materials. Here are some elastomers commonly used in injection molding:

Silicone

Silicone elastomers are known for their excellent thermal stability, flexibility, and biocompatibility. They are widely used in medical devices, cookware, and seals.

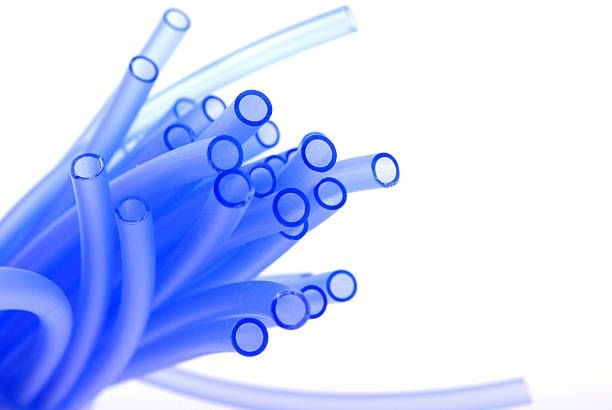

Thermoplastic Elastomers (TPE)

TPEs combine the processing advantages of thermoplastics with the elastic properties of rubber. They are used in applications requiring a soft touch, such as grips, seals, and flexible tubing.

Specialty Plastics: Meeting Specific Requirements

In addition to the common thermoplastics, thermosetting plastics, and elastomers, specialty plastics are also used in injection molding to meet specific requirements. These materials offer unique properties for specialized applications:

Polyether Ether Ketone (PEEK)

PEEK is a high-performance engineering plastic known for its excellent mechanical properties, chemical resistance, and high-temperature stability. It is used in aerospace, medical implants, and high-performance components.

Liquid Crystal Polymers (LCP)

LCPs have high mechanical strength and chemical resistance, making them suitable for electronic components and high-temperature applications.

Polysulfone (PSU)

Polysulfone is a tough, rigid, high-temperature plastic with good chemical resistance. It is used in medical devices, automotive parts, and plumbing fittings.

Additives and Fillers: Enhancing Material Properties

Raw materials for injection molding can be modified with various additives and fillers to enhance their properties. These modifications can improve the material's strength, durability, and functionality.

Glass Fibers

Glass fibers are added to plastics to improve their mechanical strength and rigidity. They are commonly used in automotive parts and structural components.

Flame Retardants

Flame retardants are added to plastics to reduce their flammability. They are essential in applications where fire safety is a concern, such as electrical components and building materials.

Colorants

Colorants are used to add color to plastic parts. They can be in the form of pigments, dyes, or masterbatches.

Plasticizers

Plasticizers are added to enhance the flexibility and processability of plastics. They are commonly used in PVC products to make them softer and more pliable.

UV Stabilizers

UV stabilizers are added to protect plastics from the degrading effects of ultraviolet light. They are crucial for outdoor applications, such as outdoor furniture and automotive parts.

Choosing the Right Raw Material for Injection Molding

Selecting the appropriate raw material for injection molding is critical to ensuring the success of the final product. Here are some factors to consider when choosing raw materials:

Mechanical Properties

The mechanical properties of the material, such as tensile strength, impact resistance, and flexibility, should match the requirements of the final product.

Chemical Resistance

The material should be resistant to chemicals and environmental factors it will be exposed to during its service life.

Thermal Properties

The material's thermal properties, including melting temperature and thermal stability, should be suitable for the injection molding process and the product's operating conditions.

Cost

The cost of the raw material is a significant factor, especially for high-volume production. Balancing material properties with cost-effectiveness is crucial.

Regulatory Compliance

For applications in medical, food, and other regulated industries, the raw material must comply with relevant regulations and standards.

Conclusion

Injection molding is a highly versatile manufacturing process that relies heavily on the choice of raw materials. Understanding the different types of raw materials for injection molding, including thermoplastics, thermosetting plastics, elastomers, and specialty plastics, is essential for producing high-quality and cost-effective products. By carefully selecting the appropriate materials and considering factors such as mechanical properties, chemical resistance, and regulatory compliance, manufacturers can optimize their injection molding processes and achieve superior results.

At SZOMK, we specialize in providing top-notch plastic injection molding services. Our expertise in selecting the right raw materials and our advanced molding technology ensure that we deliver high-quality, precise, and durable plastic components tailored to your needs. Whether you require common thermoplastics like polypropylene and ABS or high-performance materials like PEEK and LCP, SZOMK is your trusted partner for all your injection molding requirements. Contact SZOMK today to learn how our services can benefit your next project.