Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

What is Injection Molding in Agriculture?

Understanding Injection Molding Process

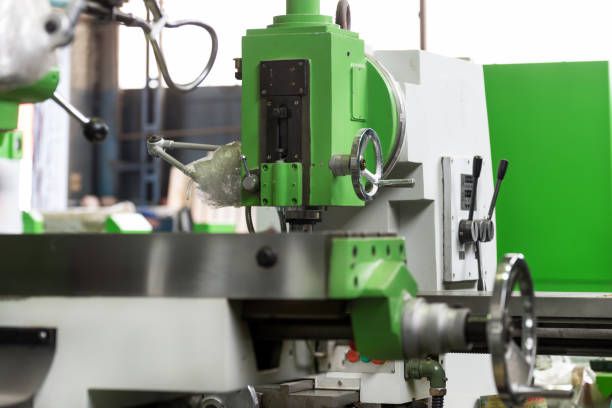

Injection molding is a manufacturing technique wherein molten plastic is injected into a mold to form a desired shape. This process comprises several steps:

- Melting of Plastic: Raw plastic material is melted and fed into the injection molding machine.

- Injection into Mold: The molten plastic is injected into a mold cavity, taking the shape of the desired product.

- Cooling and Solidification: The injected plastic cools and solidifies within the mold.

- Removal of Solid Part: The solidified part is ejected from the mold, ready for use.

Key components of the injection molding process include the injection unit, mold, and clamping unit, which work together to ensure precise and efficient production. Through this process, intricate plastic components essential for agricultural equipment and machinery are manufactured with high precision, contributing to the sector's efficiency and productivity.

Now, let's delve into how injection molding specifically benefits the agricultural industry.

Importance of Injection Molding in Agriculture

Versatility and Adaptability of Plastic Parts

Injection molding enables the creation of diverse plastic components tailored to the specific needs of agricultural applications. From irrigation system components to equipment parts, plastic parts offer versatility in design and functionality, seamlessly integrating into various farming processes.

Cost-Effectiveness Compared to Traditional Materials

Plastic injection molding provides a cost-effective solution for agricultural equipment and machinery production. Compared to traditional materials like metal, plastics are more affordable to manufacture and offer a longer lifespan, reducing replacement and maintenance costs for farmers.

Durability and Resilience in Harsh Agricultural Conditions

Plastic parts manufactured through injection molding exhibit exceptional durability, capable of withstanding the rigors of agricultural environments. Resistant to corrosion and degradation, these parts endure exposure to moisture, chemicals, and heavy usage, ensuring prolonged service life on the field.

Applications of Injection Molding in Agriculture

Tools and Equipment

Injection molding plays a vital role in the production of various tools and equipment essential for agriculture. This includes soil testing equipment, seed planting devices, and irrigation system components. These precision-engineered plastic parts contribute to the efficiency and effectiveness of farming operations.

Compliance with Industry Standards and Regulations

Agriculture operates within stringent regulatory frameworks to ensure food safety and quality. Injection molded parts adhere to industry standards, facilitating compliance with regulations set forth by organizations like the FDA. This ensures that agricultural equipment meets the necessary criteria for safe and reliable operation.

Role in Enhancing Efficiency and Productivity on Farms

Injection molding enhances efficiency and productivity on farms by providing durable, high-quality components. These parts withstand the demands of agricultural environments, reducing downtime and maintenance costs. By incorporating injection molded solutions, farmers can streamline their operations and achieve higher yields.

Case Studies and Success Stories

Examples of Successful Implementation in Agriculture

Numerous success stories highlight the effectiveness of injection molding in agriculture. From small-scale farms to large agricultural enterprises, the adoption of injection molded parts has led to significant improvements in productivity and profitability.

Impact on Farm Operations and Outcomes

Injection molding has transformed farm operations by offering solutions that address specific challenges faced in agriculture. Whether it's optimizing irrigation systems or improving seed planting techniques, injection molded components contribute to better outcomes and higher crop yields.

Testimonials from Satisfied Customers and Partners

Satisfied customers and partners attest to the value of injection molding in agriculture through testimonials and feedback. These endorsements showcase the real-world benefits experienced by farmers and agricultural professionals, reaffirming the importance of injection molding in driving success in the industry.

Future Trends and Innovations

Advancements in Injection Molding Technology

The future of injection molding in agriculture looks promising with ongoing advancements in technology. Innovations such as 3D printing, robotics, and automation are revolutionizing the manufacturing process, enabling greater precision, efficiency, and cost-effectiveness.

Potential for Customization and Tailored Solutions

As technology evolves, injection molding offers unprecedented opportunities for customization and tailored solutions in agriculture. Manufacturers can create bespoke components to meet the unique needs of farmers, optimizing equipment performance and productivity.

Integration with Smart Farming and Precision Agriculture Practices

Injection molding is poised to play a pivotal role in the integration of smart farming and precision agriculture practices. By producing sensor-equipped components and IoT-enabled devices, injection molding enables data-driven decision-making, enhancing crop management and resource efficiency.

Conclusion

Injection molding stands as a cornerstone of innovation in the agricultural sector, providing durable, cost-effective solutions for equipment and machinery. From enhancing efficiency to ensuring compliance with industry standards, injection molding plays a pivotal role in driving progress and productivity in farming practices.

For businesses in the agricultural industry seeking reliable plastic solutions, the time to embrace injection molding is now. By partnering with a trusted manufacturing partner like SZOMK, you can access high-quality, customized components tailored to your specific needs, ensuring the success and sustainability of your operations.