Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

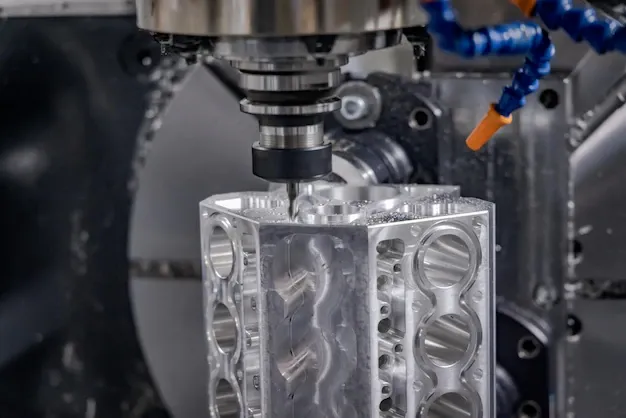

Smart Manufacturing in Injection Molding

Smart manufacturing has revolutionized various industries, and injection molding is no exception. In simple terms, smart manufacturing involves using advanced technologies to make the production process more efficient and effective. In the world of injection molding, this translates to significant improvements in speed, quality, and cost-effectiveness.

What is Smart Manufacturing?

Smart manufacturing, also called Industry 4.0, involves leveraging advanced digital technologies to improve and simplify manufacturing processes. This encompasses integrating digital technology, smart computing, automation, and big data with physical production methods such as plastic injection molding.

The Industrial Internet of Things (IIoT) plays a crucial role in smart factories by enabling real-time data collection across various manufacturing stages. Through the application of artificial intelligence (AI) and machine learning, the analyzed data can reveal valuable insights, make predictions, and empower autonomous decision-making.

Benefits of Smart Manufacturing in Injection Molding

Speeding Up Production:

One of the significant advantages of smart manufacturing in injection molding is the notable increase in production speed. Traditional methods often have fixed cycle times, regardless of the actual requirements. Smart manufacturing, on the other hand, optimizes the cycle time based on real-time data, reducing the overall production time. This means quicker turnaround for orders and increased productivity.

Enhancing Quality:

Quality control is a critical aspect of injection molding, and smart manufacturing takes it to a whole new level. By constantly monitoring and adjusting the production process, the system ensures that each molded part meets the specified standards. This not only reduces defects but also improves the overall consistency and reliability of the products.

Cost-Effectiveness in Action:

Smart manufacturing doesn't just benefit the speed and quality of production; it also has a positive impact on costs. By optimizing processes and minimizing waste, manufacturers can significantly cut down on expenses. This cost-effectiveness is a win-win situation, allowing businesses to remain competitive while offering high-quality products at a reasonable price.

Adaptable Production:

By integrating advanced data analytics and automated systems in manufacturing, flexibility in production processes is heightened. This allows manufacturers to quickly shift between different products, enhancing their ability to respond promptly to changes in market demand.

Streamlined Supply Chains:

Smart manufacturing enhances supply chain planning and management through real-time manufacturing data. This results in reduced inventories and lead times, promoting more efficient operations.

Conclusion

In conclusion, the integration of smart manufacturing in injection molding is akin to unlocking the full potential of this production method. The benefits are clear – faster production, enhanced quality, and increased cost-effectiveness. As technology continues to advance, smart manufacturing will likely become the standard in injection molding, paving the way for a more efficient and sustainable future in manufacturing.