Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

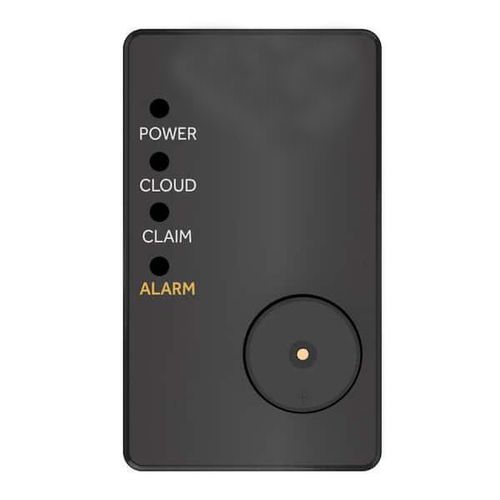

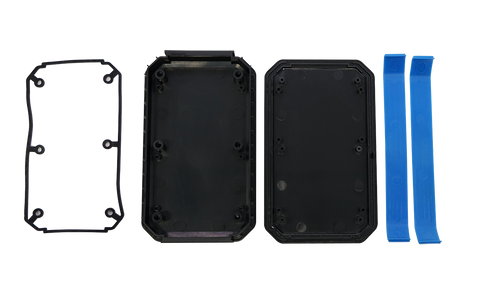

IoT Injection Molding Products

SZOMK offer a variety of IoT injection molding solutions for you. We specialize in creating high-quality, durable IoT device enclosures designed to meet the specific needs of the rapidly evolving IoT industry. Our state-of-the-art molding techniques ensure that each enclosure offers superior protection and functionality, enhancing the reliability and performance of your IoT devices. Explore our extensive range of IoT enclosures and discover how our tailored molding services can bring your innovative projects to life with precision and efficiency.

Why Injection Molding is Used in the IoT Industry?

Precision Engineering through IoT Injection Molding

IoT injection molding is crucial for creating precise and custom components crucial for the IoT industry. This method ensures the high accuracy required for IoT device enclosures that house sensitive electronics. With the implementation of IoT technologies, injection molding processes have evolved to achieve unparalleled precision, ensuring that every IoT enclosure meets exact specifications for functionality and fit.

Scalability and Efficiency

The scalability of IoT injection molding processes is vital for meeting the growing demands of the IoT industry. This approach allows for the rapid production of large volumes of IoT enclosures with consistent quality. Enhanced by IoT-driven data analysis, these processes optimize production cycles and material usage, significantly reducing waste and increasing operational efficiency. Data-driven adjustments lead to consistent quality across batches, reducing the occurrence of defects and ensuring the reliability of IoT device enclosures.

Advanced Material Utilization

IoT injection molding supports the use of a diverse range of materials that can be tailored to specific needs of IoT devices, such as thermal resistance, durability, and electrical insulation. This capability is essential for producing robust IoT device enclosures that effectively protect internal components from environmental stresses and mechanical impact.

Integration of Smart Manufacturing Techniques

The integration of smart manufacturing techniques in IoT injection molding enhances the production process by enabling real-time monitoring and adjustments. This not only helps in maintaining the quality of IoT enclosures but also facilitates proactive maintenance of molding equipment, minimizing downtime and extending the life of the machinery.

FAQs of IoT Injection Molding

What is IoT Injection Molding?

What types of IoT device enclosures can SZOMK produce?

What materials are used in SZOMK’s IoT injection molding?

Can SZOMK handle high-volume orders for IoT injection molding?

Does SZOMK offer any post-production services for IoT enclosures?

Is there support for design and prototyping in SZOMK’s IoT injection molding services?