Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

What Plastic is Used for Electrical Enclosures?

In the world of electronics, the choice of materials is crucial for the performance and longevity of devices. One significant consideration is the type of plastic used in the enclosures that house and protect electronic components. The question, "What plastic is used for electrical enclosures?" is fundamental for manufacturers, designers, and hobbyists alike. This article explores the different types of plastics used in electronics, specifically focusing on plastic enclosures for electronics, their benefits, and their applications.

Understanding Plastics Used in Electronics

Types of Plastics Used in Electrical Enclosures

When it comes to manufacturing electrical enclosures, various types of plastics are employed, each with unique properties that make them suitable for different applications. The primary types of plastics used in electronics include:

- ABS (Acrylonitrile Butadiene Styrene)

- Polycarbonate

- PVC (Polyvinyl Chloride)

- Polypropylene

- Nylon

ABS (Acrylonitrile Butadiene Styrene)

ABS is one of the most common plastics used in electrical enclosures due to its excellent impact resistance and toughness. It is lightweight, easy to mold, and provides a good balance between performance and cost. ABS is widely used in consumer electronics, such as remote controls, keyboards, and housing for small devices.

Polycarbonate

Polycarbonate is known for its high strength and transparency. It is more impact-resistant than ABS and can withstand higher temperatures, making it suitable for more demanding applications. Polycarbonate is often used in industrial electronics, where durability and visibility of internal components are crucial.

PVC (Polyvinyl Chloride)

PVC is another popular plastic used in electronics, especially for applications requiring chemical resistance and flame retardancy. It is used in a wide range of products, from cable insulation to enclosures for electrical wiring systems. PVC is durable and can be easily fabricated into various shapes and sizes.

Polypropylene

Polypropylene is valued for its chemical resistance, electrical insulation properties, and flexibility. It is used in applications where exposure to harsh chemicals or high levels of moisture is expected. Polypropylene is also used in battery cases and other protective housings for electronic components.

Nylon

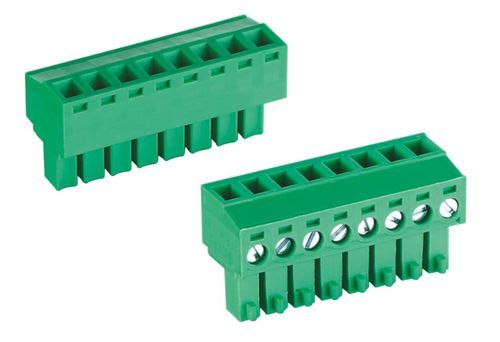

Nylon is a strong, abrasion-resistant plastic that is used in applications requiring high mechanical strength and thermal resistance. It is often used in connectors, switchgear, and other components that need to withstand mechanical stress and heat.

Benefits of Using Plastic Enclosures for Electronics

Cost-Effectiveness

Plastic enclosures are generally more cost-effective than their metal counterparts. They are cheaper to produce, and the material costs are lower. This makes plastic enclosures a popular choice for mass-produced consumer electronics.

Lightweight

Plastic enclosures are lightweight, which is a significant advantage in portable and handheld devices. The reduced weight contributes to overall user convenience and lower shipping costs for manufacturers.

Design Flexibility

Plastics offer high design flexibility, allowing manufacturers to create complex shapes and designs that are difficult or impossible to achieve with metals. This flexibility enables the production of ergonomic and aesthetically pleasing products.

Insulation Properties

Plastics used in electronics provide excellent electrical insulation, reducing the risk of short circuits and other electrical hazards. This makes plastic enclosures ideal for protecting sensitive electronic components.

Corrosion Resistance

Unlike metal enclosures, plastic enclosures do not corrode, making them suitable for use in environments where moisture and chemicals are present. This ensures the longevity and reliability of the enclosed electronics.

Applications of Plastic Enclosures in Electronics

Consumer Electronics

Plastic enclosures are ubiquitous in consumer electronics, including smartphones, laptops, tablets, and gaming consoles. The lightweight and cost-effective nature of plastics makes them ideal for these high-volume products.

Industrial Electronics

In industrial settings, plastic enclosures protect control systems, sensors, and other critical electronics from harsh environments. Polycarbonate and PVC are commonly used due to their durability and resistance to chemicals.

Medical Devices

Medical devices often use plastic enclosures to ensure sterility and reduce the risk of electrical interference. Plastics like ABS and polypropylene are preferred for their biocompatibility and ease of sterilization.

Automotive Electronics

In the automotive industry, plastic enclosures protect various electronic systems, such as GPS units, infotainment systems, and engine control units. The thermal resistance and mechanical strength of nylon and polycarbonate make them suitable for these applications.

Telecommunications

Telecommunications equipment, including routers, modems, and switchgear, frequently use plastic enclosures. The electrical insulation properties and design flexibility of plastics support the reliable operation of these devices.

Frequently Asked Questions

What are the most common plastics used for electrical enclosures?

The most common plastics used for electrical enclosures are ABS, polycarbonate, PVC, polypropylene, and nylon. Each type offers unique properties suitable for different applications.

Why is ABS plastic popular for electronics?

ABS plastic is popular for electronics due to its excellent impact resistance, toughness, and ease of molding. It provides a good balance between performance and cost, making it ideal for consumer electronics.

Can plastic enclosures be used in harsh environments?

Yes, certain plastics like polycarbonate and PVC are suitable for harsh environments due to their chemical resistance and durability. They can protect electronic components from moisture, chemicals, and physical impacts.

Are plastic enclosures environmentally friendly?

The environmental impact of plastic enclosures depends on the type of plastic and its disposal. Some plastics can be recycled, but it's essential to consider the full lifecycle of the product and explore sustainable materials where possible.

How do I choose the right plastic enclosure for my electronics?

To choose the right plastic enclosure, consider factors such as the environmental conditions, mechanical stress, electrical insulation needs, and design requirements of your application. Consulting with a manufacturer can help you select the best material.

Conclusion

Selecting the right plastic for electrical enclosures is crucial for ensuring the protection, performance, and longevity of electronic devices. Various plastics, including ABS, polycarbonate, PVC, polypropylene, and nylon, offer unique benefits suited to different applications. Understanding the properties and advantages of these materials can help manufacturers and designers make informed decisions when it comes to choosing the best plastic enclosure for electronics.

For high-quality plastic enclosures, Szomk offers a wide range of options tailored to meet diverse electronic housing needs. With a focus on durability, design flexibility, and cost-effectiveness, Szomk provides solutions that ensure your electronics are well-protected and perform optimally. Choose Szomk for reliable and innovative plastic enclosures that meet the highest standards of the industry.