Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

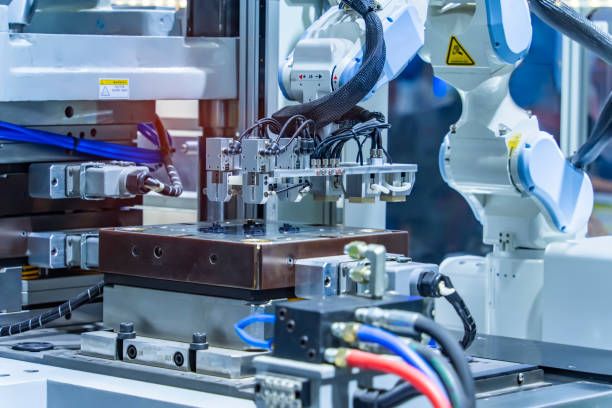

What is Back Pressure in Injection Molding?

In the process of injection molding, pressure is applied from the rear end of the screw within the barrel. This assists in propelling the molten plastic material forward. This force exerted from the rear is known as backpressure. In the absence of back pressure in backpressure injection molding, the screw would retract, causing the material to remain unchanged within the barrel.

What Does Back Pressure Mean in Injection Molding?

Back pressure, also known as plasticizing pressure, is a natural outcome of the injection molding process, where plastics are melted and shaped. As the material blends and advances through the injection screw, it exerts force against the screw, creating back pressure. This pressure originates from the metering section of the mixing screw.

Controlling hydraulic back pressure is feasible during injection molding, with settings typically beginning at fifty PSI and increasing in increments of ten PSI. The maximum hydraulic pressure is usually capped at 300 PSI to avoid potential issues like plastic shearing and thermal degradation, altering the mechanical properties of the molded part, making it brittle and prone to failure.

It's important to distinguish back pressure from injection pressure, the force at which the mold fills, often referred to as the first stage of pressure. Holding pressure, applied after the molten plastic fills the mold and maintained until release, and clamp pressure, keeping the mold closed against the separating force caused by plastic injection, are also integral aspects.

The Role of Back Pressure in Injection Molding

But why is back pressure crucial in injection molding? Elevated melt pressure ensures better control of melt temperature without the need to increase the temperature for uniformity. Higher back pressure results in greater melt uniformity, offering a more consistent plastic pressure. This, in turn, enhances the blending of additives and colors, especially with a well-designed screw.

Increased back pressure aids in extruding air within the melt material, improving plastic gloss and eliminating internal bubbles. Issues like black specks and material degradation at the screw's flight root are minimized. Screw augering, common in smaller screws due to pellets wedged between flight land and feed throat, is significantly reduced. Regardless of the injection unit, optimal back pressure improves shot size position control and reduces surface shrinkage issues.

However, there are situations where lowering back pressure is necessary. Excessive pressure can break fibers in reinforced resins, while lower pressure prevents vent flooding in a vented barrel used to eliminate moisture and trapped air and other volatiles. Balancing back pressure is key to achieving the desired outcomes in injection molding.

How Back Pressure Affects Injection Molding?

The effectiveness of the backpressure method significantly impacts the progression of injection molding. The movement of the screw is paramount, as it undertakes the majority of the tasks in this process. The molding procedure hinges on the reciprocating motion of the screw. Key considerations in backpressure injection molding include the screw's speed, measured in rotations per minute (rpm), typically ranging from 20 to 60 rpm in most machines. The rotation speed is contingent on the plastic's properties. Additionally, the size of the shot, determined by the injection chamber, is another crucial parameter to take into account.

Conclusion

So, there you have it—the lowdown on back pressure in injection molding. It's the behind-the-scenes maestro, conducting the symphony of molten plastic into a masterpiece. The next time you hold a perfectly molded plastic item, remember the delicate dance of back pressure that brought it to life.