Unlock your product's potential with our One-stop solutions!

+86-755-83222882

GET QUOTE

How Plastic Enclosures Are Made?

Plastic enclosures are integral to various industries, protecting electronic devices, housing components, and providing durable solutions for everyday products. Understanding how plastic enclosures are made can shed light on the intricacies of manufacturing processes, material choices, and the technology driving innovation. When it comes to achieving top-notch quality and functionality in plastic enclosure production, one cannot overlook the significance of reliable solutions. And that's where SZOMK's solution for OEM and ODM plastic molds comes into play. Their expertise and advanced technology ensure that every plastic enclosure is crafted to perfection, meeting the highest standards. This article delves into the step-by-step journey of creating plastic enclosures, providing insights into the essential methods and considerations that ensure these products meet high standards of quality and functionality.

The Importance of Plastic Enclosures

Plastic enclosures play a crucial role in protecting sensitive components from environmental factors such as dust, moisture, and physical damage. They are used in a myriad of applications, from consumer electronics to industrial machinery. The versatility and cost-effectiveness of plastic enclosures make them a preferred choice for manufacturers and designers. Their ability to be molded into complex shapes and sizes allows for creative and practical solutions in various fields.

Materials Used in Plastic Enclosures

Common Plastics for Enclosures

The selection of materials is a fundamental step in the production of plastic enclosures. Common plastics used include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its strength and impact resistance, ABS is widely used in consumer electronics and automotive parts.

- Polycarbonate: Offering high impact resistance and transparency, polycarbonate is ideal for enclosures requiring visibility of internal components.

- PVC (Polyvinyl Chloride): With good chemical resistance and flexibility, PVC is used in various applications, including electrical enclosures.

- Polypropylene: Lightweight and resistant to chemicals and moisture, polypropylene is often used in medical and laboratory equipment.

Specialized Plastics

Specialized plastics such as polyetherimide (PEI) and polyphenylene sulfide (PPS) are used in high-performance applications where thermal stability and mechanical strength are critical.

The Manufacturing Process of Plastic Enclosures

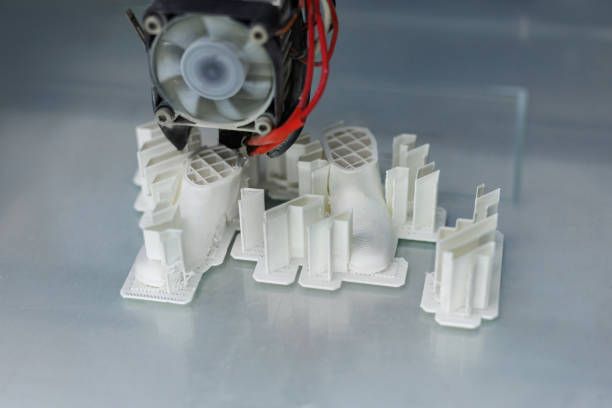

Design and Prototyping

The journey of creating plastic enclosures begins with design and prototyping. Engineers and designers use CAD (Computer-Aided Design) software to create detailed models of the enclosure. These models are then used to produce prototypes, often through 3D printing or CNC machining. Prototyping allows for testing and refinement of the design before mass production.

Injection Molding

Injection molding is the most common method for producing plastic enclosures. This process involves:

- Creating the Mold: A mold is designed and manufactured based on the CAD model. The mold consists of two halves, which form the cavity where the plastic will be injected.

- Melting and Injecting Plastic: Plastic pellets are heated until they melt and then injected into the mold cavity under high pressure.

- Cooling and Ejection: The molten plastic cools and solidifies within the mold. Once solidified, the mold opens, and the finished enclosure is ejected.

CNC Machining

For low-volume production or custom enclosures, CNC machining is often used. This method involves using computer-controlled machines to precisely cut and shape plastic materials into the desired enclosure form. CNC machining offers high accuracy and flexibility, making it suitable for specialized applications.

Thermoforming

Thermoforming is another technique used in the production of plastic enclosures. It involves heating a plastic sheet until it becomes pliable and then forming it over a mold. Once cooled, the plastic retains the shape of the mold. This method is often used for larger enclosures and offers a cost-effective solution for medium to large-scale production.

Quality Control in Plastic Enclosure Manufacturing

Ensuring the quality and durability of plastic enclosures is paramount. Manufacturers employ various quality control measures to guarantee the reliability and performance of their products.

Dimensional Inspections

Measuring the physical dimensions of the enclosures is a crucial step to ensure they meet design specifications. This process involves using precise measuring tools and techniques to verify that each enclosure conforms to the required size and shape.

Material Testing

Testing the plastic materials for properties such as tensile strength, impact resistance, and thermal stability is essential. These tests ensure that the materials used can withstand the intended use and environmental conditions, providing longevity and durability to the enclosures.

Environmental Testing

Subjecting enclosures to environmental conditions such as temperature extremes, humidity, and UV exposure helps ensure long-term durability. By simulating real-world conditions, manufacturers can identify and address potential weaknesses in the enclosures.

Advancements in Plastic Enclosure Manufacturing

3D Printing

The advent of 3D printing has revolutionized the production of plastic enclosures. This technology allows for rapid prototyping and small-batch production with high precision and minimal waste. 3D printing enables the creation of complex geometries and customized designs that would be challenging or impossible with traditional manufacturing methods.

Smart Manufacturing and Automation

Automation and smart manufacturing techniques are increasingly being integrated into plastic enclosure production. Automated systems improve efficiency, reduce errors, and enhance consistency in the manufacturing process. IoT-enabled devices and AI-driven analytics provide real-time monitoring and predictive maintenance, further optimizing production workflows.

Sustainable Manufacturing Practices

Sustainability is becoming a key focus in the manufacturing of plastic enclosures. Efforts to reduce waste, recycle materials, and use eco-friendly plastics are gaining traction. Biodegradable plastics and bio-based polymers offer environmentally friendly alternatives, aligning with global initiatives to reduce plastic pollution and carbon footprints.

Applications of Plastic Enclosures

Plastic enclosures are ubiquitous in various industries due to their versatility and protective qualities. They are essential in providing safe housing for electronic components and other sensitive materials.

Consumer Electronics

Plastic enclosures are used to house devices such as smartphones, tablets, and remote controls. They offer protection against physical damage and environmental factors, ensuring the longevity and reliability of these consumer devices.

Industrial Equipment

In industrial settings, plastic enclosures are used for control panels, sensors, and machinery components. They provide a durable and resistant barrier against harsh industrial environments, safeguarding critical equipment.

Medical Devices

Plastic enclosures play a vital role in protecting sensitive medical instruments and ensuring hygiene standards. They are used in various medical devices, offering both protection and ease of sterilization.

Automotive Industry

In the automotive industry, plastic enclosures are used for electronic control units, sensors, and infotainment systems. They provide robust protection against the demanding conditions of automotive environments.

Conclusion

The manufacturing of plastic enclosures is a complex and multifaceted process that involves careful material selection, advanced production techniques, and stringent quality control measures. From design and prototyping to injection molding and CNC machining, each step ensures that the final product meets the required standards of durability, functionality, and aesthetics. Innovations such as 3D printing and smart manufacturing are continually enhancing the production of plastic enclosures, offering new possibilities for customization and sustainability.

When it comes to high-quality plastic enclosures, SZOMK stands out as a leader in the industry. With a commitment to excellence and a comprehensive range of injection molding services, SZOMK specializes in plastic injection molding, offering tailored solutions to meet the diverse needs of various industries. Their expertise in material selection, precision manufacturing, and rigorous quality control ensures that every enclosure they produce meets the highest standards. Whether you need custom enclosures for consumer electronics, industrial equipment, medical devices, or automotive applications, SZOMK provides unparalleled quality and service. Partner with SZOMK for your plastic enclosure needs and experience the difference in quality and innovation.