Injection moulding is the backbone of manufacturing processes worldwide. This versatile method allows for the production of an array of products, from small consumer items to intricate industrial components. Our brand, SZOMK, is committed to providing you with valuable insights into the world of injection moulding. In this comprehensive guide, we'll delve into the different types of injection moulding, their applications, and the advantages they offer.

Understanding the Basics of Injection Moulding

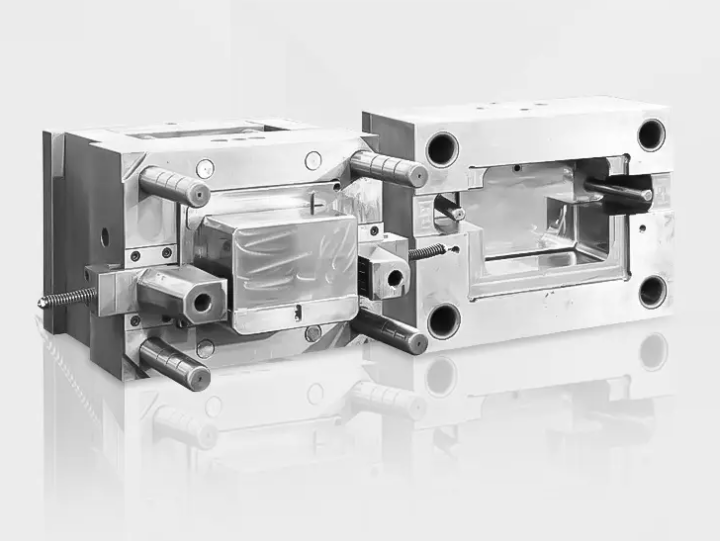

Before we dive into the various types of injection moulding techniques, let's ensure we have a solid grasp of the fundamental process. Injection moulding is a manufacturing technique where molten material is injected into a mould to create a finished product. It is a widely used method due to its high efficiency, precision, and versatility.

Now, let's explore the different types of injection moulding techniques, starting with the conventional approach.

1. Conventional Injection Moulding

Conventional injection moulding is the most widely used method in manufacturing. It involves injecting molten material, typically plastic, into a mould. Once cooled, the material solidifies into the desired shape. This method is versatile and is employed in a variety of industries, including automotive, electronics, and consumer goods. It's renowned for its precision, cost-effectiveness, and speed.

2. Structural Foam Injection Moulding

Structural foam injection moulding is a variation of the conventional method. It incorporates a chemical blowing agent to create a cellular structure within the material, resulting in a lightweight but sturdy product. This technique is used extensively for large parts and is a go-to choice for items such as furniture, automotive components, and panels.

3. Gas-Assisted Injection Moulding

Gas-assisted injection moulding enhances the conventional method by injecting a gas, typically nitrogen, into the molten material. This creates a hollow area within the product, reducing material usage and weight. It's ideal for producing large, hollow parts while maintaining structural integrity. The automotive and furniture industries frequently utilize this approach.

4. Overmoulding

Overmoulding is a process where a second material is moulded over an existing part. This technique is used to add a layer of material for improved grip, protection, or aesthetics. You can find overmoulded products in tools, toothbrushes, and numerous handheld devices. SZOMK offers comprehensive overmoulding solutions to meet your specific needs.

5. Insert Moulding

Insert moulding involves placing an insert, often made of metal or plastic, into the mould cavity before injection. The molten material surrounds the insert, creating a strong bond. This method is commonly used in the production of electronic connectors, threaded fasteners, and custom components for various industries.

6. Micro Injection Moulding

Micro injection moulding is a specialized technique used to create exceptionally small components. It's widely used in industries like medical devices and microelectronics. The precision and repeatability of micro injection moulding make it invaluable for producing intricate, miniature parts.

7. Reaction Injection Moulding (RIM)

Reaction injection moulding (RIM) uses a chemical reaction to create polyurethane parts. This process offers a high level of flexibility in design and is favored in industries such as automotive and electronics. RIM provides durable, lightweight, and cost-effective solutions.

8. Co-injection Moulding

Co-injection moulding involves injecting multiple materials into the mould simultaneously. This process allows for unique combinations of properties, such as a hard-soft or colored-core structure. It is widely used in packaging, automotive, and consumer goods industries.

Choosing the Right Injection Moulding Method

Selecting the appropriate moulding method for a specific project depends on various factors, including material, product design, and desired properties. Consider factors like production volume, cost, and material requirements when choosing the right injection moulding method for your project.

Conclusion

Injection moulding is a versatile and crucial manufacturing process with applications spanning a multitude of industries. At SZOMK, we are committed to providing you with the knowledge and solutions you need to make informed decisions about your projects. From conventional injection moulding to advanced techniques like RIM and co-injection, understanding the various types of injection moulding opens up a world of possibilities for creating high-quality, cost-effective products.

In our commitment to transparency and knowledge-sharing, we invite you to reach out with any questions or inquiries about your injection moulding needs. Our team at SZOMK is here to assist you in creating high-quality, customized solutions for your unique projects.

Have any questions or want to explore our injection moulding solutions? Contact us at SZOMK, and let's bring your ideas to life!